How is the Data stored in CD and DVD?

Large storage devices can also be implemented using optical means. The familiar compact disk (CD), used in audio systems, was the first practical application of this technology. Soon after, the optical technology was adapted to the computer environment to provide high-capacity read-only storage referred to as CD-ROM. The first generation of CDs was developed in the mid-1980s by the Sony and Philips companies, which also published a complete specification for these devices. The technology exploited the possibility of using digital representation of analog sound signals. To provide high-quality sound recording and reproduction, 16-bit samples of the analog signal are taken at a rate of 44,100 samples per second. This sampling rate is twice the highest frequency in the original sound signal, thus allowing for accurate reconstruction. The CDs were required to hold at least an hour of music. The first version was designed to hold up to 75 minutes, which requires a total of about 3 x 109 bits (3 gigabits) of storage. Since then, higher-capacity devices have been developed. A video CD is capable of storing a full-length movie. This requires approximately an order of magnitude more bit-storage capacity than that of audio CDs. Multimedia CDs are also suitable for storing large amounts of computer data.

CD Technology

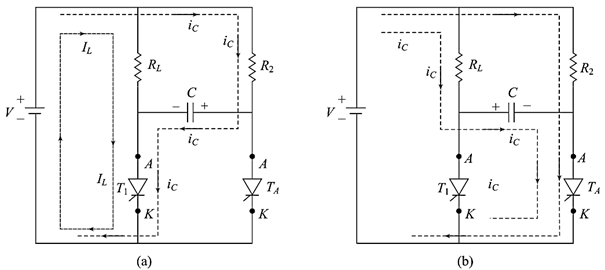

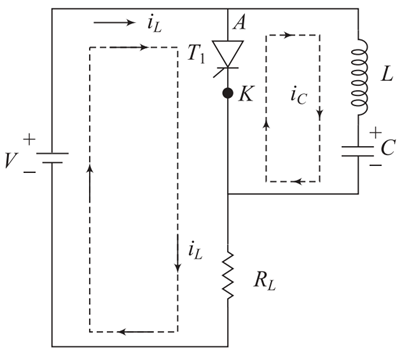

The optical technology that is used for CD systems is based on a laser light source. A laser beam is directed onto the surface of the spinning disk. Physical indentations in the surface are arranged along the tracks of the disk. They reflect the focused beam toward a photodetector, which detects the stored binary patterns. The laser emits a coherent light beam that is sharply focused on the surface of the disk. Coherent light consists of synchronized waves that have the same wavelength. If a coherent light beam is combined with another beam of the same kind, and the two beams are in phase, then the result will be a brighter beam. But, if the waves of the two beams are 180 degrees out of phase, they will cancel each other. Thus, if a photodetector is used to detect the beams, it will detect a bright spot in the first case and a dark spot in the second case. The bottom layer is polycarbonate plastic, which functions as a clear glass base. The surface of this plastic is programmed to store data by indenting it with pits. The unintended parts are called lands. A thin layer of reflecting aluminum material is placed on top of a programmed disk. The aluminum is then covered by a protective acrylic. Finally, the topmost layer is deposited and stamped with a label. The total thickness of the disk is 1.2 mm. Almost all of it is contributed by the polycarbonate plastic. The other layers are very thin. The laser source and the photodetector are positioned below the polycarbonate plastic. The emitted beam travels through this plastic, reflects off the aluminum layer, and travels back toward the photodetector. Note that from the laser side, the pits actually appear as bumps with respect to the lands. Figure shows what happens as the laser beam scans across the disk and encounters a transition from a pit to a land.

Three different positions of the laser source and the detector are shown, as would occur when the disk is rotating. When the light reflects solely from the pit, or solely from the land, the detector will see the reflected beam as a bright spot. But, a different situation arises when the beam moves through the edge where the pit changes to the land, and vice versa.

The pit is recessed one quarter of the wavelength of the light. Thus, the reflected wave from the pit will be 180 degrees out of phase with the wave reflected from the land, cancelling each other. Hence, at the pit-land and land-pit transitions the detector will not see a reflected beam and will detect a dark spot. Figure c depicts several transitions between lands and pits. If each transition, detected as a dark spot, is taken to denote the binary value 1, and the flat portions represent 0s, then the detected binary pattern will be as shown in the figure. This pattern is not a direct representation of the stored data. CDs use a complex encoding scheme to represent data. Each byte of data is represented by a 14-bit code, which provides considerable error detection capability. We will not delve into details of this code. The pits are arranged along tracks on the surface of the disk. Actually, there is just one physical track, spiraling from the middle of the disk toward the outer edge. But, it is customary to refer to each circular path spanning 360 degrees as a separate track, which is analogous to the terminology used for magnetic disks. The CD is 120 mm in diameter. There is a 15-mm hole in the center. Data are stored on tracks that cover the area from 25-mm radius to 58-mm radius. The space between the tracks is 1.6 microns. Pits are 0.5 microns wide and 0.8 to 3 microns long. There are more than 15,000 tracks on a disk. If the entire track spiral were unraveled, it would be over 5 km long! These numbers indicate a track density of about 6000 tracks/cm, which is much higher than the density achievable in magnetic disks. The density ranges from 800 to 2000 tracks/cm in hard disks, and is less than 40 tracks/cm in floppy disks.

CD-ROM

Since information is stored in binary form in CDs, they are suitable for use as a storage medium in computer systems. The biggest problem is to ensure the integrity of stored data. Because the pits are very small, it is difficult to implement all of the pits perfectly. In audio and video applications, some errors in data can be tolerated because they are unlikely to affect the reproduced sound or image in a perceptible way. However, such errors are not acceptable in computer applications. Since physical imperfections cannot be avoided, it is necessary to use additional bits to provide error checking and correcting capability. CDs used in computer applications have such capability. They are called CD-ROMs, because after manufacture their contents can only be read, as with semiconductor ROM chips.

Stored data are organized on CD-ROM tracks in the form of blocks that are called sectors. There are several different formats for a sector. One format, known as Mode 1, uses 2352-byte sectors. There is a 16-byte header that contains a synchronization field used to detect the beginning of the sector and addressing information used to identify the sector. This is followed by 2048 bytes of stored data. At the end of the sector, there are 288 bytes used to implement the error-correcting scheme. The number of sectors per track is variable; there are more sectors on the longer outer tracks. Error detection and correction is done at more than one level. As mentioned in the introduction to CDs, each byte of stored information is encoded using a 14-bit code that has some error-correcting capability. This code can correct single-bit errors. Errors that occur in short bursts, affecting several bits, are detected and corrected using the error-checking bits at the end of the sector. CD-ROM drives operate at a number of different rotational speeds. The basic speed, known as 1X, is 75 sectors per second. This provides a data rate of 153,600 bytes/s (150 Kbytes/s), using the Mode 1 format.

With this speed and format, a CD-ROM based on the standard CD designed for 75 minutes of music has a data storage capacity of about 650 Mbytes. Note that the speed of the drive affects only the data transfer rate but not the storage capacity of the disk. Higher speed CD-ROM drives are identified in relation to the basic speed. Thus, a 40X CD-ROM has a data transfer rate that is 40 times higher than that of the 1X CD-ROM. Observe that this transfer rate (<6 Mbytes/s) is considerably lower than the transfer rates in magnetic hard disks, which are in the range of tens of megabytes per second. Another big difference in performance is the seek time, which in CD-ROMs may be several hundred milliseconds. So, in terms of performance, CD-ROMs are clearly inferior to magnetic disks. Their attraction lies in the small physical size, low cost, and ease of handling as a removable and transportable mass-storage medium. The importance of CD ROMs for computer systems stems from their large storage capacity and fast access times compared to other inexpensive portable media, such as floppy disks and magnetic tapes. They are widely used for the distribution of software, databases, large texts (books), application programs, and video games.

CD-Recordables

Previously described CDs are read-only devices in which the information is stored using a special procedure. First, a master disk is produced using a high-power laser to bum holes that correspond to the required pits. A mold is then made from the master disk, which has bumps in the place of holes. This is followed by injecting molten polycarbonate plastic into the mold to make a CD that has the same pattern of holes (pits) as the master disk. This process is clearly suitable only for volume production of CDs. A new type of CD was developed in the late 1990s on which data can be easily recorded by a computer user. It is known as CD-Recordable (CD-R). A spiral track is implemented on a disk during the manufacturing process. A laser in a CD-R drive is used to bum pits into an organic dye on the track. When a burned spot is heated beyond a critical temperature, it becomes opaque. Such burned spots reflect less light when subsequently read. The written data are stored permanently. Unused portions of a disk can be used to store additional data at a later time.

CD-Rewritables

The most flexible CDs are those that can be written multiple times by the user. They are known as CD-RWs (CD-Rewritable). The basic structure of CD-RWs is similar to the structure of CD-Rs. Instead of using an organic dye in the recording layer, an alloy of silver, indium, antimony and tellurium is used. This alloy has interesting and useful behavior when it is heated and cooled. If it is heated above its melting point (500 degrees C) and then cooled down, it goes into an amorphous state in which- it absorbs light. But, if it is heated only to about 200 degrees C and this temperature is maintained for an extended period, a process known as annealing takes place, which leaves the alloy in a crystalline state that allows light to pass through. If the crystalline state represents land area, pits can be created by heating selected spots past the melting point. The stored data can be erased using the annealing process, which returns the alloy to a uniform crystalline state. A reflective material is placed above the recording layer to reflect the light when the disk is read.

The CD-RW drive uses three different laser powers. The highest power is used to record the pits. The middle power is used to put the alloy into its crystalline state; it is referred to as the “erase power.” The lowest power is used to read the stored information. There is a limit on how many times a CD-RW disk can be rewritten. Presently, this can be done up to 1000 times. CD-RW drives can usually also deal with other compact disk media. They can read CD-ROMs, and both read and write CD-Rs. They are designed to meet the requirements of standard interconnection interfaces, such as EIDE, SCSI, and USB. CD-RWs provide a low-cost storage medium. They are suitable for archival storage of information that may range from databases to photographic images. They can be used for low-volume distribution of information, just like CD-Rs. The CD-RW drives are now fast enough to be used for daily hard disk backup purposes. The CD-RW technology has made CD-Rs less relevant because it offers superior capability at only slightly higher cost.

DVD Technology

The success of CD technology and the continuing quest for greater storage capability has led to the development of DVD (Digital Versatile Disk) technology. The first DVD standard was defined in 1996 by a consortium of companies. The objective is to be able to store a full-length movie on one side of a DVD disk. The physical size of a DVD disk is the same as for CDs. The disk is 1.2 mm thick, and it is 120 mm in diameter. Its storage capacity is made much larger than that of CDs by several design changes: A red light laser with a wavelength of 635 nm is used instead of the infrared light laser used in CDs, winch has a wavelength of 780 nm. The shorter wavelength makes it possible to focus the light to a smaller spot. Pits are smaller, having a minimum length of 0.4 micron. Tracks are placed closer together; the distance between tracks is 0.74 micron. Using these improvements leads to a DVD capacity of 4.7 Gbytes.

Further increases in capacity have been achieved by going to two-layered and two sided disks. The single-layered single-sided disk, defined in the standard as DVD-5, has a structure that is almost the same as the CD in Figure 5.32a. A double-layered disk makes use of two layers on which tracks are implemented on top of each other. The first layer is the clear base, as in CD disks. But, instead of using reflecting aluminum, the lands and pits of this layer are covered by a translucent material that acts as a semi reflector. The surface of this material is then also programmed with indented pits to store data. A reflective material is placed on top of the second layer of pits and lands. The disk is read by focusing the laser beam on the desired layer. When the beam is focused on the first layer, sufficient light is reflected by the translucent material to detect the stored binary patterns. When the beam is focused on the second layer, the light reflected by the reflective material corresponds to the information stored on this layer. In both cases, the layer on which the beam is not focused reflects a much smaller amount of light, which is eliminated by the detector circuit as noise. The total storage capacity of both layers is 8.5 Gbytes. This disk is called DVD-9 in the standard. Two single-sided disks can be put together to form q sandwich-like structure where the top disk is turned upside down. This can be done with single-layered disks, as specified in DVD-10, giving a composite disk with a capacity of 9.4 Gbytes. It can also be done with the double-layered disks, as specified in DVD-18, yielding a capacity of 17 Gbytes. Access times for DVD drives are similar to CD drives. However, when the DVD disks rotate at the same speed, the data transfer rates are much higher because of the higher density of pits.

DVD-RAM

A rewritable version of DVD devices, known as DVD-RAM, has also been developed. It provides a large storage capacity. Its only disadvantages are the higher price and the relatively slow writing speed. To ensure that the data have been recorded correctly on the disk, a process known as write verification is performed. This is done by the DVD-RAM drive, winch reads the stored contents and checks them against the original data.

latest video

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua