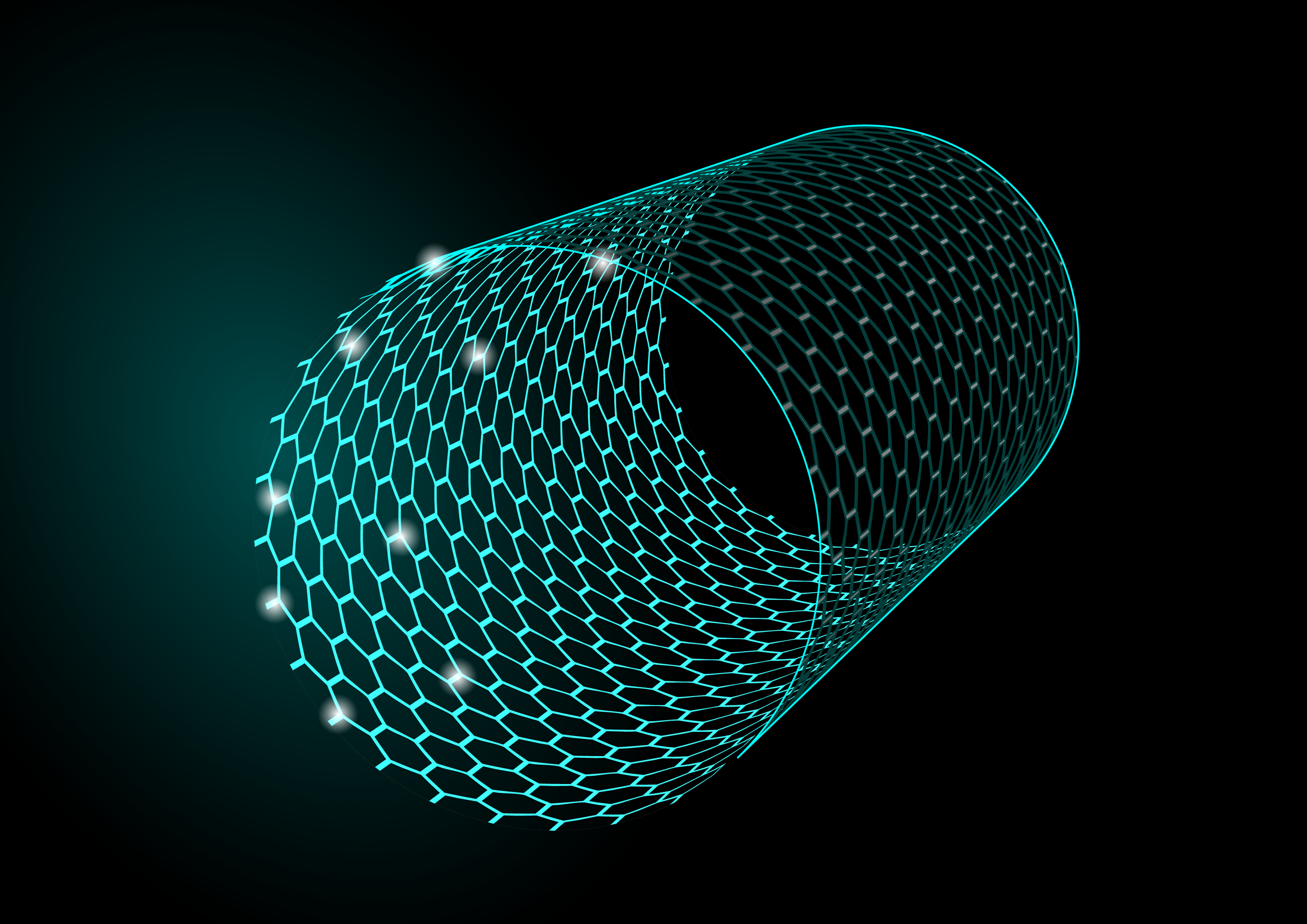

Graphene Nanotubes: The Latest Advancement in Li-ion Batteries

The use of graphene seems to be emerging as one of the ways forward for new lithium-ion battery designs. If you remember, SiNode Systems is working with anodes that use graphene to build a high-capacity, high-performance lithium-ion battery. It turns out Rice University researchers also are experimenting with graphene — in the form of graphene nanoribbons (GNRs) — to achieve a similar effect.

A Rice research team — including chemistry, engineering, and computer science professor James Tour and postdoctoral research Jian Lin — has successfully created proof-of-concept anodes that are capable of more capacity than typical battery anodes by creating them out of GNRs and tin oxide. Typical lithium-ion battery anodes, or the part of the battery that stores lithium ions, are made primarily of tin oxide and graphite.

After 50 charge-discharge cycles, the test anodes created by the team maintained a capacity that was still more than double that of the graphite currently used for lithium-ion battery anodes, researchers said. This extended life could pave the way for numerous commercial applications of this type of battery design in devices as well as electric vehicles, they said. The team published its findings in a recent article in the chemistry journal ACS Nano.

The Rice team produced the GNRs by unzipping carbon nanotubes, Lin told Design News in an email. He and his colleagues revealed their method of unzipping these tubes in an article in Nature in 2009, and have since figured out how to make GNRs in bulk that can make lithium-ion batteries more effective. “The highly conductive GNRs with high-aspect ratio can promote the lithium storage capability of tin oxide nanostructures,” Lin told us.

Lin’s reference to “high aspect ratio” basically means that the tubes are “long and thin,” his colleague Tour further explained in an email to Design News. This improves the conduction capability of the battery’s active material, thus improving the transport of charged ions in the battery. “The graphene nanoribbons permit a high conductance through the battery’s active material at a low weight percent of incorporation — this would not be possible with sheet-like graphene,” Tour told us. “And being ribbons, they do not obscure the lithium ion transport into and out of the material during charging and discharging as would sheet-like graphene.”

In addition to cycling lifetime, the method also improves the capacity, or total power output, of the battery over present-day lithium ion batteries,” Tour added.

Indeed, scientists are working on numerous ways to extend the life of lithium-ion batteries, which still need constant charging and degrade and lose their charge over time. Incorporating new materials into the design of the battery is a key method with which they are experimenting, Lin said. “The research in lithium ion battery is booming these days,” he told us. “Searching for different material is the major focus of research and industry.”

While batteries using GNRs already are inexpensive to produce, Lin said it would be ideal to find an even cheaper method of mass producing them if they become the next-generation lithium-ion batteries. In the meantime, he said the Rice team is extending its research to examine GNRs composite with different transition metal oxide nanostructures. This would further boost the performance of anode and cathode for lithium ion battery.

There currently is no time frame for when the batteries might be ready for prime time, but Lin is convinced that long-term investment in new lithium-ion designs “will benefit the public one day.”

latest video

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua