Can 48V Powertrain be the Auto Industry’s Next Big Entity?

Another new powertrain technology may be poised to bring major change to the auto industry by delivering the advantages of hybridization without some of the complexity.

This technology, known simply as 48V, combines a dual-voltage setup with the well-known advantages of start-stop technology. By doing so, it more effectively captures a vehicle’s braking energy, provides more power for a growing list of electrical loads, and simultaneously boosts fuel efficiency — possibly by as much as 15 percent.

If you’re a bit sceptical because you think you’ve heard some of this before, you’re not alone. During the late 1990s, auto industry executives talked up a technology known as 42V. After a few years of contentious debate, however, 42V died an inauspicious death. But suppliers say this technology is different; unlike 42V, it could offer a big jump in fuel economy. Moreover, the regulatory environment has changed, and battery technology has improved.

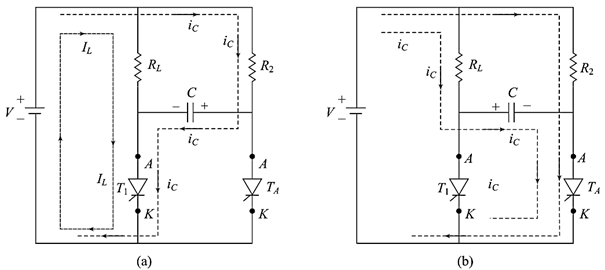

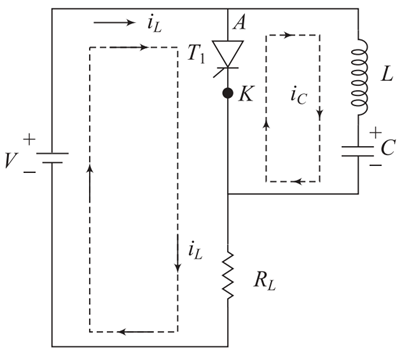

The 48V configuration, supported by a number of automotive suppliers, calls for a conventional 12V network using a lead-acid battery like those employed in most conventional vehicles. However, it adds an extra layer: a 48V lithium-ion battery with a separate 48V network. The 12V network handles traditional loads: lighting, ignition, entertainment, audio systems, and electronic modules. The 48V system supports active chassis systems, air conditioning compressors, and regenerative braking.

One of the keys to 48V is lithium-ion battery technology, which wasn’t available at the time of the ill-fated 42V systems. Engineers say lithium-ion technology offers about three times as much energy density as lead-acid chemistry. “There’s a size and weight advantage to using a lithium-ion battery,” Rigby said. “Back in the ’90s, we were looking at stringing three lead-acid batteries together to get that voltage.”

More importantly, the 48V lithium-ion battery has more charging capability, making it a better candidate for capturing regenerative braking energy. “It really comes down to the notion of regenerative braking — harvesting the kinetic energy from the vehicle during deceleration and storing it in the battery.”

Of course, conventional full hybrids offer the same capabilities, but they typically use very high-voltage electrical architectures and high-voltage batteries. A few years ago, the Toyota Prius used a 500V electrical architecture, while the Ford Escape Hybrid employed a 330V system, and a Lexus hybrid SUV operated at more than 600V. Those voltages enable hybrids to support up 20kW of electrical loads, compared with about 1.5kW on conventional 12V gas-burning cars. As a result, they have an easier time handling extra electrical features, such as heated front seats, heated windshields, rear defrosters, and eventually electric air conditioners, active chassis, and drive-by-wire systems.

Still, the 48V architectures will offer significantly more power than conventional 12V systems using lead-acid batteries, even if they don’t reach the level of a Prius. “You have the potential to boost the power levels to 10, 11, and even 12kW,” Rigby said. “It’s not as much as a [full] hybrid, but it’s certainly not insignificant.”

Suppliers see the 48V architecture as a sort of addendum to start-stop technology, but it’s a big addendum. A 12V start-stop may boost fuel efficiency by 5 percent, but a 48V start-stop would offer a 15 percent advantage.

If start-stop’s uptake rate is an indication, 48V has a chance for big adoption. In Europe, approximately 50 percent of the cars produced this year will be start-stop vehicles, and that figure is still rising. Rigby said 48V could offer the same kind of consumer appeal. “It’s going to come down to the economics. How much will it cost? What’s the payback? What’s the price of fuel? Those things will determine how fast it gets adopted.”

latest video

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua