The Superconducting Transformer

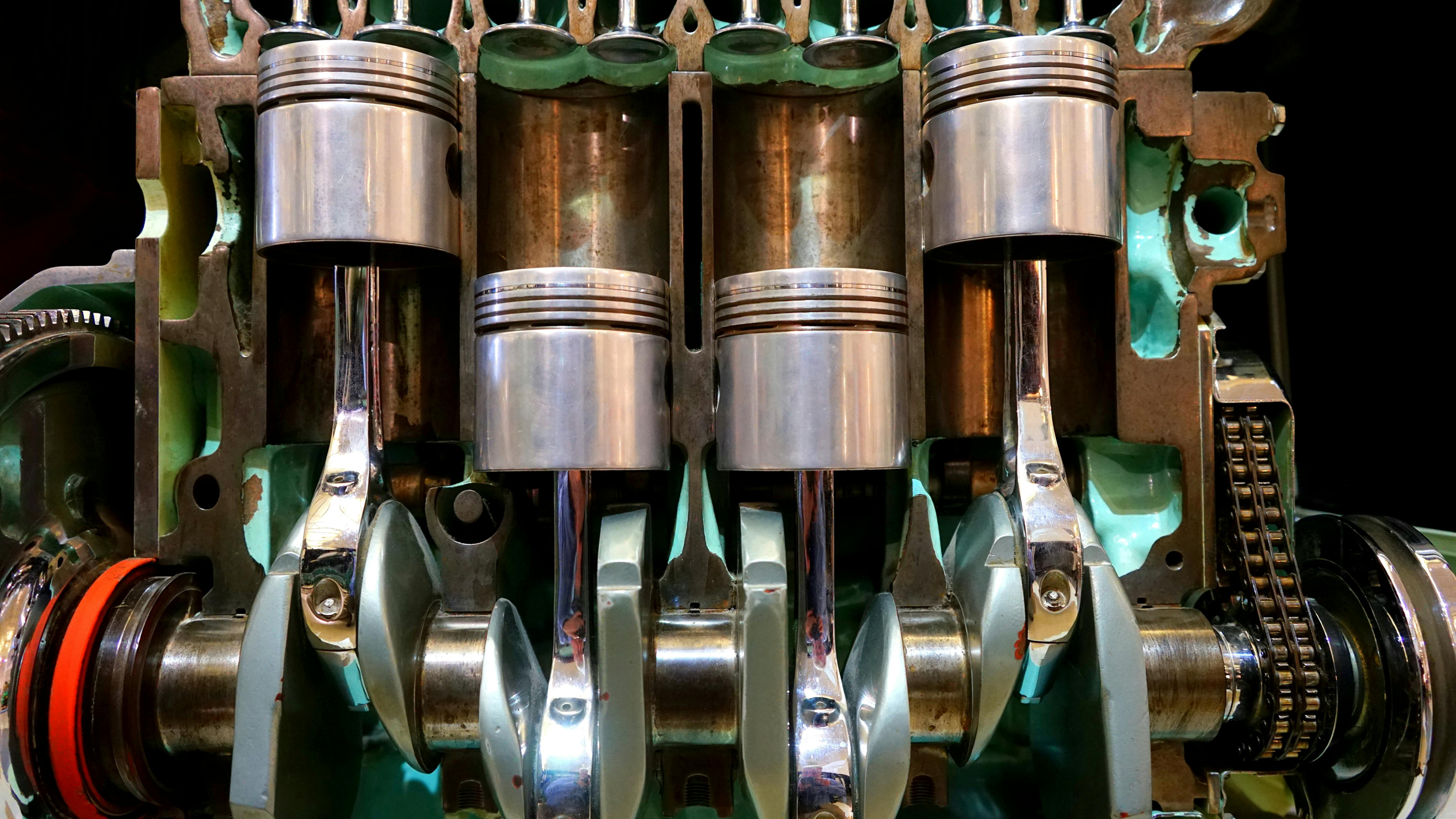

For the small transformers, we can neglect the various types of losses that may be present in a particular transformer. When dealing with large power transformers, however, close attention must be paid to these losses, despite overall efficiencies of typically 97 percent or more. Although such a high efficiency may seem like a nearly ideal value, it can represent a great deal of wasted energy when the transformer is handling several thousand amps of current. Modern transformer designs incorporate a number of features designed to minimize losses, especially those that increase with increasing feature. When current flows through a coil, for example, the resistance of the wire leads to what is commonly referred to as i²R losses, meaning that the power absorbed by the wire increases with the square of the current, and is dissipated as heat. As the wire temperature increases, so does its resistance, thereby increasing i²R loss in the wire. Also, high temperatures can lead to degradation of the wire insulation, resulting in shorter transformer life. As a result, many modern power transformers employ a liquid oil bath to remove excess heat from the transformer coils. This type of approach has several drawbacks, however. Corrosion and other ageing-related effects often lead to oil leakage, which can have a serious environmental impact. The use of combustible oil also posses a fire hazard, and fighting fires in a high-voltage substation is potentially dangerous situation.

One possible means of improving the performance of such transformers is to make use of superconducting wire to replace the resistive coils of a standard transformer design. Superconductors are materials that are resistive at high temperature, but suddenly show no resistance to the flow of current once a critical temperature is reached. For most elements, this critical temperature is only a few degrees above absolute zero, requiring expensive liquid helium for cooling. However, with the discovery of high-temperature ceramic superconductors in the 1980’s, materials characterized by critical temperatures of 90 K and higher, it became possible to replace helium-based cryogenic equipment with liquid nitrogen systems, which are significantly cheaper to build and to operate. Switching to transformer design based on replacing resistive wire coils with superconducting wires has a number of benefits. First, comparably rated transformers are about one-third the size. Second, switching the coolant from oil to liquid nitrogen eliminates the fire hazard associated with the oil, and since liquid nitrogen evaporates into nitrogen gas, already a component of the surrounding air and environmentally benign, leakage does not pose a groundwater contamination threat. Third, but perhaps most important, elimination of the resistive losses in the coil can lead to an increase in overall transformer efficiency, so that the amount of power required from the generator facility is reduced, leading to a substantial cost savings.

However, all designs have disadvantages that must be weighed against their proposed advantages, and superconducting transformer designs are no exception. The most significant obstacle at present is the relatively high cost of fabricating superconducting wire several kilometers in length compared to the cost of copper wire. Since these materials (bismuth strontium calcium copper oxide, yttrium barium copper oxide, etc.) are very brittle and the maximum current density (the peak current divided by the wire cross section) depends on the crystal quality, a great deal of effort is required to fabricate long wires. Also, these wires are typically fabricated inside silver tubing so that there is a current path in the event of a cooling failure (as long as the inner wire is superconducting, no current flows through the silver, which is still resistive at liquid nitrogen temperatures). The use of silver adds to the cost of the wire; although less expensive, copper is not a viable option in these applications due to its tendency to react with the oxide superconductor material. The net result is that although a superconducting transformer is likely to save a utility money over a long period of time (many transformers see over 30 years of service), the initial cost is much higher than for a traditional resistive transformer. At present, many companies (including utilities) are driven by short-term cost considerations and are not always eager to make large capital investments with only long-term cost benefits.

latest video

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua