Understanding the Components of ICE Vehicles

We shifted our focus briefly from electric mobility to the traditional Internal Combustion Engine Vehicle (ICEV). This foundation is essential: to appreciate the technological leap offered by EVs, students must first understand the architecture and limitations of conventional vehicle systems.

Although EVs are rapidly gaining momentum, the internal combustion engine remains the dominant power plant in global transportation. Most spark-ignition vehicles run on gasoline, and compression-ignition vehicles rely on diesel. Interestingly, even alternative fuels like CNG and ethanol can be burned in ICEs with only minimal modifications—highlighting the robustness of this century-old technology.

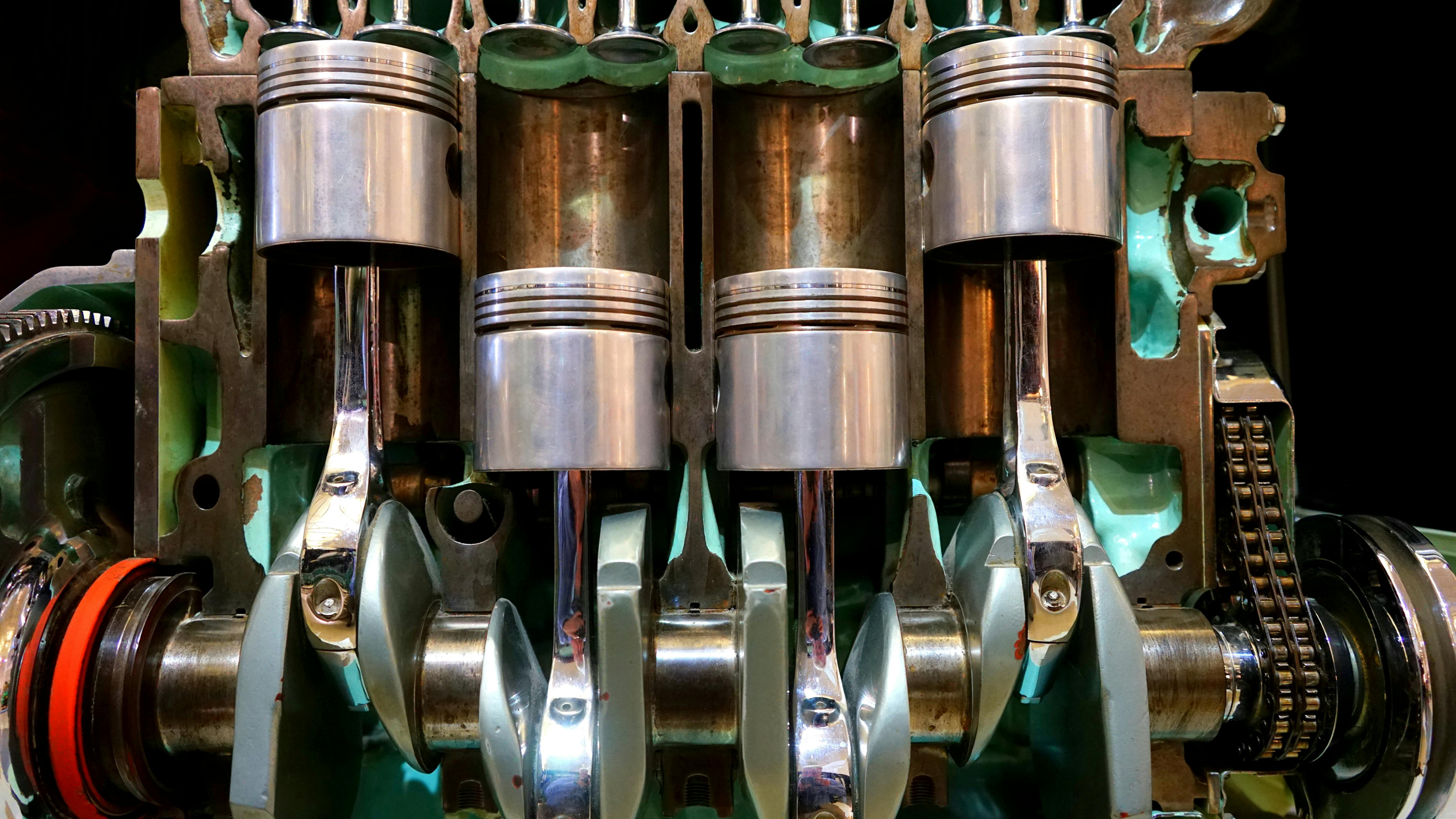

1. Power-Producing Unit (Engine)

At the heart of every ICE vehicle lies the internal combustion engine, where chemical energy from fuel is converted into mechanical work. Inside the engine:

- Pistons move up and down in cylinders due to combustion pressure.

- The reciprocating motion is transformed into rotation by the crankshaft.

- Valves regulate the intake of the air–fuel mixture and the removal of exhaust gases.

- Spark-ignition (SI) engines use spark plugs to ignite the mixture.

- Compression-ignition (CI) engines (diesel engines) rely on high compression temperatures for ignition.

Together, these components generate the torque needed to drive the vehicle.

2. Fuel and Air Intake Systems

Combustion requires fuel + air in correct proportion.

- The fuel system includes the tank, pumps, filters, injectors (or carburetors in older vehicles).

- The air intake system filters and channels clean air into the cylinders.

- After combustion, gases exit through the exhaust system, which incorporates emission controls such as catalytic converters to reduce harmful pollutants.

This subsystem plays a major role in fuel economy and emissions—two factors central to the shift toward EVs.

3. Cooling and Lubrication Systems

IC engines generate enormous heat and require careful thermal management.

- The cooling system (radiator, coolant pump, hose network) removes excess heat and prevents overheating.

- The lubrication system circulates engine oil to minimize friction, reduce wear, and ensure smooth operation.

These auxiliary systems are crucial for engine longevity, but also add complexity compared with electric powertrains, which naturally run cooler and contain fewer moving parts.

4. Ignition System (for SI Engines)

The ignition system creates precisely timed electrical sparks to ignite the air–fuel mixture in SI engines. Components include:

- Ignition coil

- Distributor or ECU-based ignition control

- Spark plugs

Diesel engines do not require this system since they rely on compression ignition.

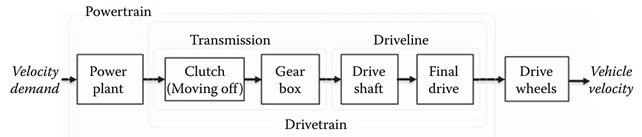

5. Power Transmission System

Once torque is produced, it must be efficiently delivered to the wheels.

The transmission system includes:

- Clutch (manual) or torque converter (automatic)

- Gearbox

- Final drive

- Differential

- Driveshafts

We analyzed how gear ratios help match engine torque-speed characteristics to varying driving conditions.

Figure 1 in class illustrated the complete powertrain: engine → drivetrain → drive wheels.

The transmission system directly influences:

- Tractive effort

- Fuel consumption

- Driving performance

This is a major area where EVs differ since electric motors can operate efficiently over a wide speed range, reducing the need for multi-gear systems.

6. Chassis, Suspension, Steering, and Braking

These mechanical systems support vehicle dynamics and safety:

- Chassis/frame holds all components.

- Suspension (springs, struts, dampers) ensures comfort and stability.

- Steering provides directional control.

- Braking systems (hydraulic discs/drums, ABS) ensure safe deceleration and stopping.

Together, they define the vehicle’s ride quality and handling characteristics.

7. Electrical and Electronic Systems

Modern ICEVs are heavily electronics-driven:

- Battery and alternator supply power.

- Sensors monitor engine and vehicle conditions.

- The Engine Control Unit (ECU) performs real-time adjustments to fuel injection, ignition timing, emissions control, and more.

- Lighting, infotainment, safety systems, and driver assistance also fall under this domain.

This is the strongest point of continuity between ICEVs and EVs — both rely extensively on electronics and embedded control.

Closing Reflection

Understanding ICEV components sets the stage for appreciating just how different an EV powertrain is—simpler, cleaner, and more efficient.

latest video

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua