Damping Force and Damping Systems

Damping Force

When a deflecting force is applied to the moving system, it deflects and it should come to rest at a position where the deflecting force is balanced by the controlling force. The deflecting and controlling forces are produced by systems which have inertia and, therefore, the moving system cannot immediately settle at its final position but overshoots or swings ahead of it. The pointer thus oscillates about its final steady (equilibrium) position with decreasing amplitude till its kinetic energy (on account of inertia) is dissipated in friction and therefore, it will settle down at its final steady position. If extra forces are not provided to “damp” these oscillations, the moving system will take a considerable time to settle to the final position and hence time consumed in taking readings will be very large. Therefore, damping forces are necessary so that the moving system comes to its equilibrium position rapidly and smoothly without any oscillations.

Damping Systems

The damping torque should be of such a magnitude that the pointer quickly comes to its final steady position, without overshooting. If the instrument is underdamped, the moving system will oscillate about the final steady position with a decreasing amplitude and will take some time before it comes to rest. When the moving system moves rapidly but smoothly to its final steady position, the instrument is said to be critically damped or dead beat. If the damping torque is more than what is required for critical damping, the instrument is said to be overdamped. In an overdamped instrument, the moving system moves slowly to its final steady position in a lethargic fashion. The readings are very tedious to take in this case.

The damping device should be such that it produces a damping torque only while the moving system is in motion. To be effective the damping torque should be proportional to the velocity of the moving system but independent of the operating current. It must not affect the controlling torque or increase the static friction.

The methods for producing damping torque are:

(i) Air friction damping,

(ii) Fluid friction damping,

(iii) Eddy current damping and

(iv) Electromagnetic damping.

(i) Air Friction Damping

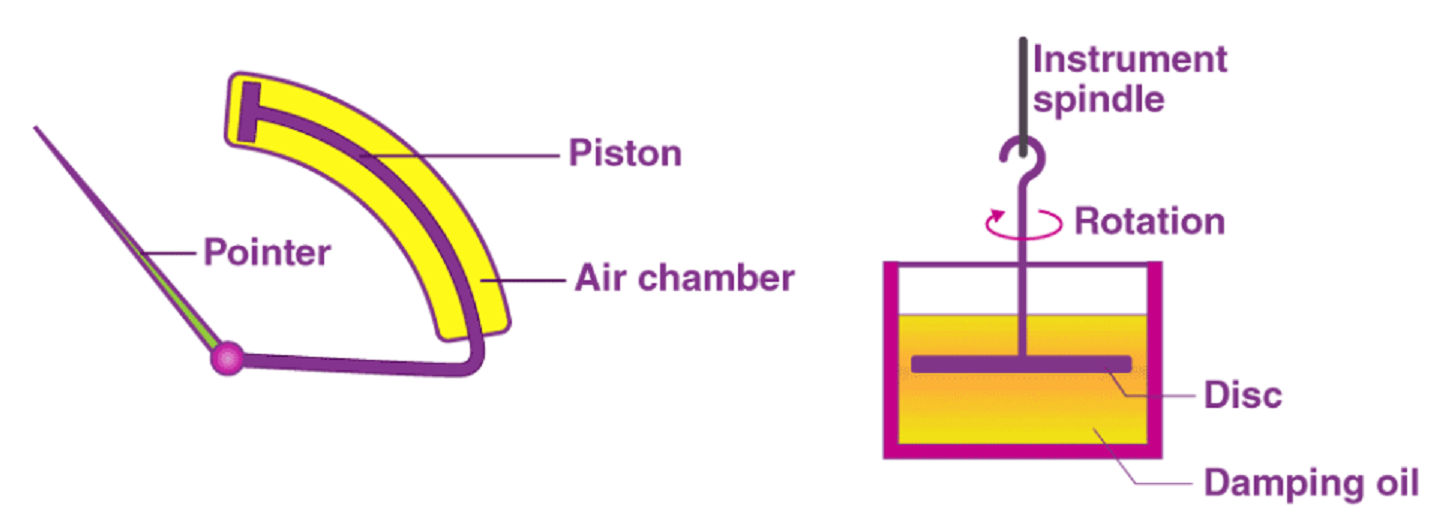

Two types of air friction damping devices are shown in Figure.

The arrangement of Fig. (a) consists of a light aluminium piston which is attached to the moving system. This piston moves in a fixed air chamber which is closed at one end. The clearance between piston and chamber walls is uniform throughout and is very small. When there are oscillations, the piston moves into and out of an air chamber. When the piston moves into the chamber, the air inside is compressed and the pressure of air, thus built up, opposes the motion of piston and hence whole of the moving system. When the piston moves out of air chamber, pressure in the closed space falls, and the pressure on the open side of piston is greater than on the other side. Thus, there is again an opposition to motion.

Fig: Air friction damping

The arrangement of Fig. (b), consists of an aluminium vane which moves in a quadrant (sector) shaped air chamber. This air chamber is a recess cast in a Bakelite moulding or diecasting. The chamber is completed by providing a cover plate at the top. The aluminium piston should be carefully fitted so that it does not touch the wall otherwise a serious error will be caused in readings.

(ii) Fluid Friction Damping

This form of damping is similar to air friction damping. Oil is used in place of air and as the viscosity of oil is greater, the damping force is also correspondingly greater. A disc is attached to the moving system [Fig. (a)], this disc dips into an oil pot and is completely submerged in oil. When the moving system moves, the disc moves in oil and a frictional drag is produced. This frictional drag always opposes the motion. In the arrangement shown in Fig. (b), a number of vanes are attached to the spindle. These vanes are submerged in oil and move in a vertical plane. This arrangement gives a greater damping torque.

Fig: Fluid friction damping

(iii) Eddy Current Damping

When a conductor moves in a magnetic field an emf is induced in it and if a closed path is provided, a current (known as eddy current) flow. This current interacts with the magnetic field to produce an electromagnetic torque which opposes the motion. This torque is proportional to the strength of the magnetic field and the current produced. The current is proportional to emf which in turn is proportional to velocity of the conductor. Thus, if the strength of the magnetic field is constant (if it is produced by a permanent magnet), the torque is proportional to velocity of the conductor.

(iv) Electromagnetic Damping

The movement of a coil in a magnetic field produces a current in the coil which interacts with the magnetic field to produce a torque. This torque opposes the movement of the coil and slows the response. The magnitude of the current and hence the damping torque is dependent upon the resistance of the circuit to which the instrument is connected. The electromagnetic damping is used in galvanometers.

latest video

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua