Controlling Force and Control Systems

Controlling Force

Controlling force. This force is required in an indicating instrument in order that the current produces deflection of the pointer proportional to its magnitude. The system producing a controlling force is called a “Controlling System.” The functions of the controlling system are:

- To produce a force equal and opposite to the deflecting force at the final steady position of pointer in order to make the deflection of the pointer definite for a particular magnitude of current. In the absence of a controlling system, the pointer will shoot (swing) beyond the final steady position for any magnitude of current and thus the deflection will be indefinite.

- To bring the moving system back to zero when the force causing the instrument moving system to deflect is removed. In the absence of a controlling system the pointer will not come back to zero when current is removed. Controlling force is usually provided by springs.

Control Systems

There are two types of control systems which are used for such a mounted system:

(i) Gravity control, and

(ii) Spring control.

Gravity control

In this type of control, a small weight is placed on an arm attached to the moving system. The position of this weight is adjustable. This weight produces a controlling torque due to gravity.

Figure shows the pointer at zero position. In this case the control torque is zero. Suppose the system deflects through an angle θ as shown in Figure. The weight acts at a distance l from the centre, the component of weight trying to restore the pointer back to zero position is W sin θ. Therefore, controlling torque is:

TC = W sin θ x I = W l sin θ = Kg sin θ

where Kg = W l = a constant.

Thus, the controlling torque is proportional to sine of angle of deflection of moving system. The controlling torque can be varied by simply adjusting the position of control weight upon the arm which carries it.

Fig: Gravity Control

It is obvious that the instruments employing gravity control must be used in vertical position in order that the control may operate. The instruments must be mounted in level position otherwise there will be a very serious zero error. For these reasons, gravity control is not suited for indicating instruments in general and portable instruments in particular.

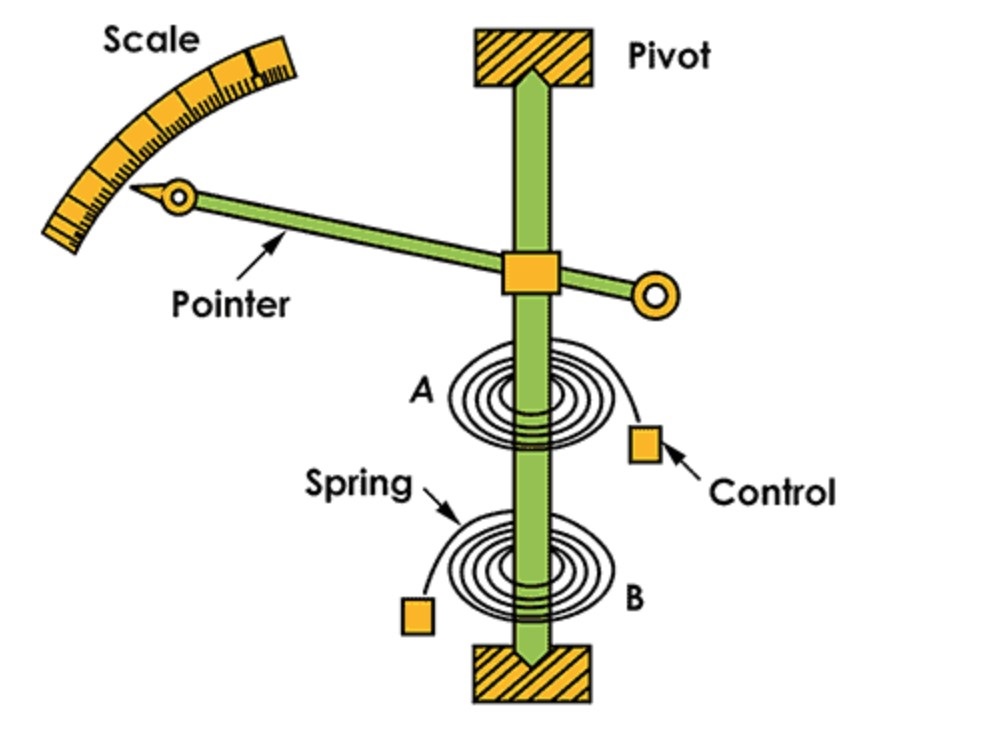

Spring Control

A hair spring attached to the moving system (Figure) exerts a controlling torque. The essential requirements for instrument springs are:

(i) They should be non-magnetic.

(ii) They should be proof from mechanical fatigue.

(iii) Where springs are used to lead current into moving system they should have a small resistance, their cross-sectional area must be sufficient to carry the current without temperature rise affecting their constant. They should also have a low resistance temperature co-efficient.

Fig: Spring Control

A number of non-magnetic materials like silicon bronze, hard rolled silver or copper, platinum silver, platinum-iridium and German silver have been used but have not been found satisfactory owing to some reason or the other. For most applications phosphor bronze has been found to be the most suitable material except in instruments of low resistance (like millivoltmeters). In this case some special bronze alloys having low resistance may be used with some sacrifice in mechanical quality. Flat spiral springs are used in almost all indicating instruments as the space required by these springs is less than for other types.

One form of control spring mounting is shown in Figure. The inner end of the spring is attached to the spindle and the outer end carries a spigot which engages in a circular disc surrounding the jewel screw. This disc carries an arm which is slotted and splayed out at the end. The purpose of slotted extension arm is to allow the spring to be coiled or uncoiled slightly, so that the pointer may be set at zero. The controlling torque is thus made proportional to the angle of deflection of the moving system.

For a flat spiral spring, the controlling torque developed by deflection is, Tc = K θ

where K = spring constant.

Comparison between Spring and Gravity Control

The disadvantages of gravity control have been described earlier. They are

- This type of control can be used in only vertically mounted instruments and

- In case gravity control is used, the instruments must be perfectly levelled.

Its advantages, when compared with spring control, are:

- It is cheap.

- The control is independent of temperature variations.

- It does not deteriorate with time.

latest video

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua